Thin Metal Parts Joins the Wickeder Group

On June 1st, 2024, EMS acquired the precision metal fabrication company Thin Metal Parts.

TMP is a robust business providing micro, precisely manufactured metal pieces for defense, audio, medical, aerospace, and several other markets.

TMP supplies expert photochemical etching, electroforming, and laser cutting technologies to provide customers with precise, high-quality parts made to exact specifications and standards.

Their commitment to quality, precision, and providing unmatched customer service made TMP a perfect partner with EMS and the Wickeder Group.

Thin Metal Parts Technology

Chemical Etching

Also known as chemical milling, chemical etching is a quick, cost-effective, and adaptable metal fabrication process for the creation of precise metal parts. Chemical etching is an exact and meticulous method involving putting a thin sheet of metal through a series of processes to remove any areas of the metal not coated, allowing completely custom and intricate shapes and designs. It does all this without subjecting the material to heat or pressure, so it retains its strength and integrity, allowing for even the most technical of cuts.Electroforming

Electroforming is a unique metal-forming process. Unlike most other methods, which remove metal to create the desired shape, electroforming builds material around a mold, usually made of wax or plastic. A thin layer of metal is applied to the mold before being dipped into an electrolytic bath. Once an electric current is applied to the bath, material beings building up delicately around the mold. Removing the mold leaves an incredibly intricate and precise metal piece, making it perfect for making jewelry, electronics, and art. Because electroforming builds up a complete, free-standing structure, it’s set apart from electroplating, which only adds a thin metal coating to an existing object.Laser Cutting

Laser cutting is a precise manufacturing process that uses a high-powered laser to cut materials into specific shapes or designs. The process involves focusing a laser beam onto a material’s surface, which heats it to the point of melting, burning, or vaporizing, creating ultra-clean cuts or engravings. Computer-aided design (CAD) software typically guides the laser, allowing for intricate patterns and highly accurate cuts. Laser cutting is widely used for materials like metal, plastic, wood, and textiles in industries such as manufacturing, construction, and arts. The process offers several advantages, including high precision, smooth edges, and the ability to cut complex shapes with minimal material waste. It is commonly employed in both industrial applications and creative fields like fashion and art. Laser cutting gets its name from the high-powered laser used to melt, burn, or vaporize material creating ultra-clean cuts or engravings.Mylar Imaging

Mylar imaging refers to the process of printing or etching designs onto Mylar, a durable polyester film known for its flexibility, strength, and heat resistance. Mylar is often used in applications where dimensional stability and clarity are essential, such as in stencils, labels, and protective coatings. Mylar imaging typically involves screen printing or laser etching to create images or text on the film’s surface. The imaging process allows for fine detail, making Mylar popular in graphic arts, signage, and technical drawings. Due to its durability, Mylar is also used in environments where traditional paper or other materials might degrade over time.Thin Metal Parts Products

TMP specializes in several high-quality products, including metal encoder codewheels and custom mesh and sieves.

TMP Encoders

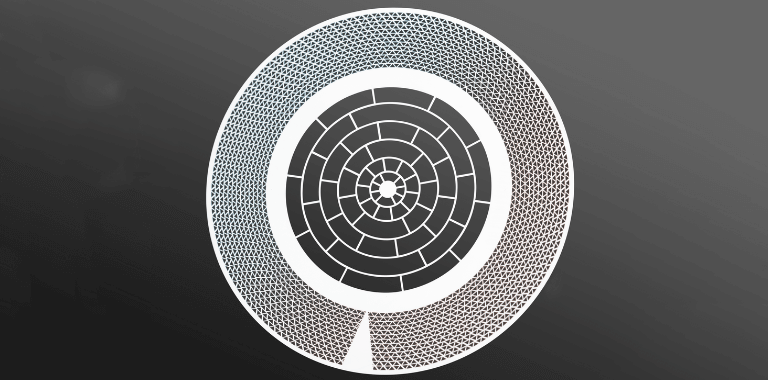

Thin Metal Parts are specialists in producing exact incremental and absolute rotary encoders. These encoders can be created using any of the available processes at TMP, depending on the specifications of the design, including electroforming, chemical milling, laser cutting, Mylar imaging, and glass imaging.

These encoders are corrosion resistant and remain stable and strong in high-temperature and shock environments, making them perfect for industries like Aerospace, Electronics, Industrial Automation, Medical, and many more.

TMP Mesh & Sieves

TMP boasts an impressive, proprietary process for creating electroformed metal mesh and sieves.

TMP’s Mesh and Sieves can be made to exact specifications, allowing for a greater thickness than woven wire or other electroforming techniques, but can also be made to a very fine thickness down to 10 microns.

These products excel for industries where precision matters, including optical light transmissions, scientific devices, and filtration applications (both gas and liquid).

Thin Metal Parts supplies impressive metal fabrication, making them a welcomed addition to EMS and the Wickeder Group!