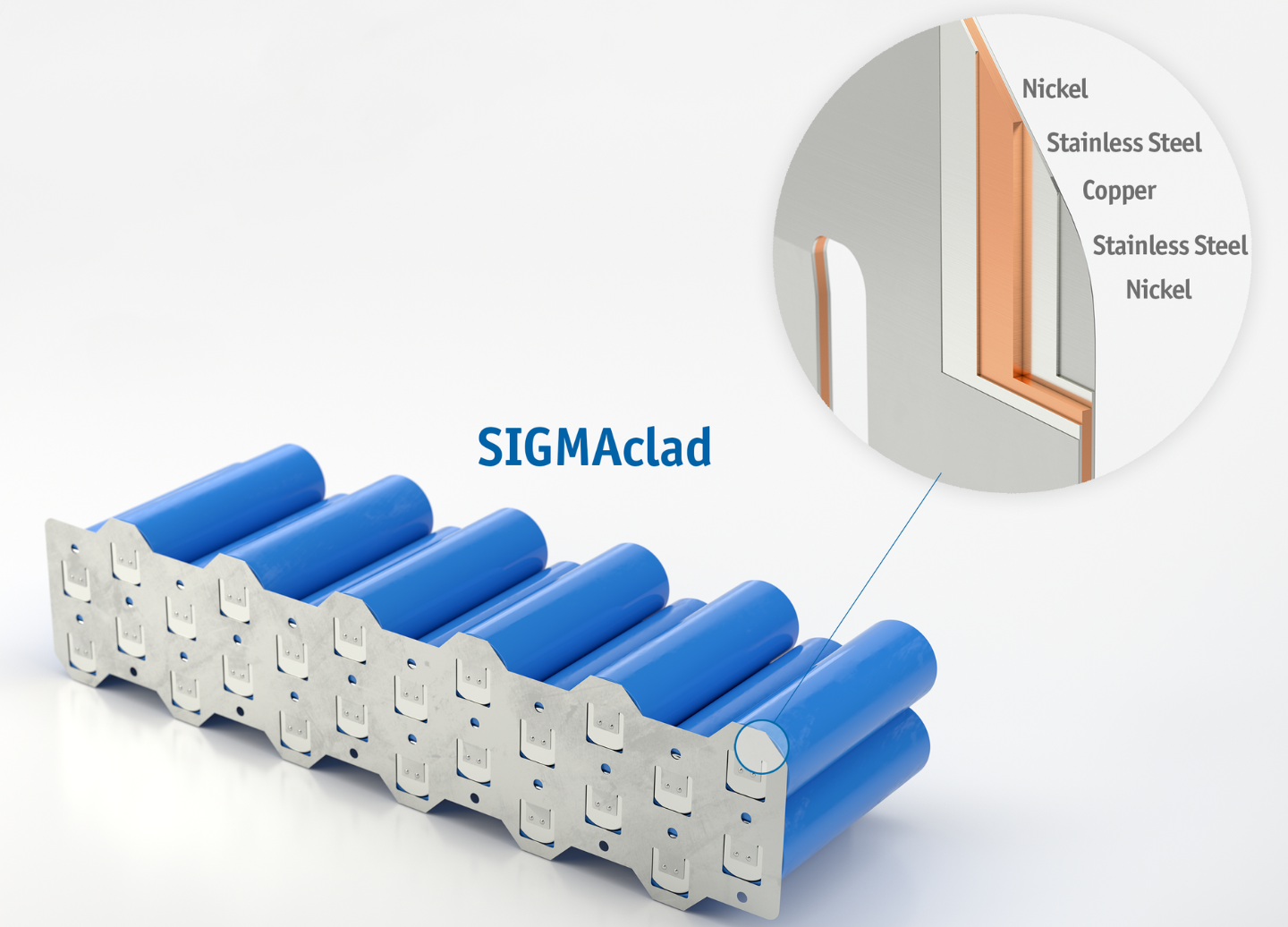

SIGMACLAD®

Your COOLEST Connector Plate

High Conductivity that’s Actually Weldable

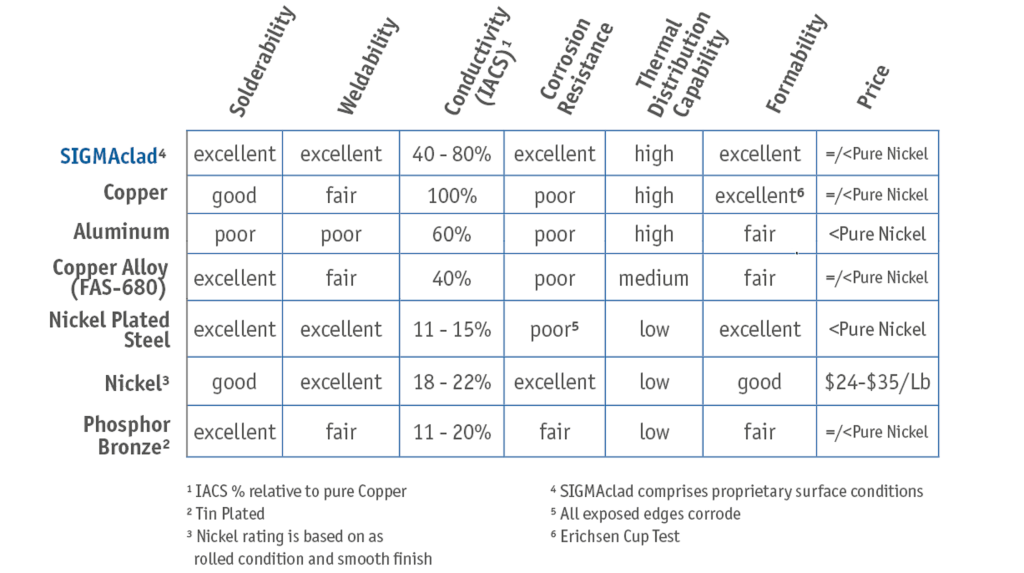

SIGMACLAD® is a 5-Layer clad material composed of Ni/SS/Cu/SS/Ni created specifically for busbars in Li-Ion Battery Packs. It is designed with superior properties compared to other materials used in these applications like Nickel or Nickel Plated Steel . The Copper layer provides enhanced electrical and thermal conductivity for heat dissipation. The Stainless Steel layers facilitate resistance welding and increases weld strength. The exterior layers of Nickel allow for easy soldering and provide enhanced corrosion resistance. All of these features are provided at a cost that can be lower than pure Nickel and competitive with Nickel Plated Steel.

Advantages

› High electrical & thermal conductivity for lower battery pack operating temperatures

› Easily welded by resistance or laser

› Stainless layers promote higher weld strength and fatigue resistance

› High conductivity allows for designing thinner, lighter, lower cost battery connector

› Nickel surface layers for soldering and additional corrosion resistance

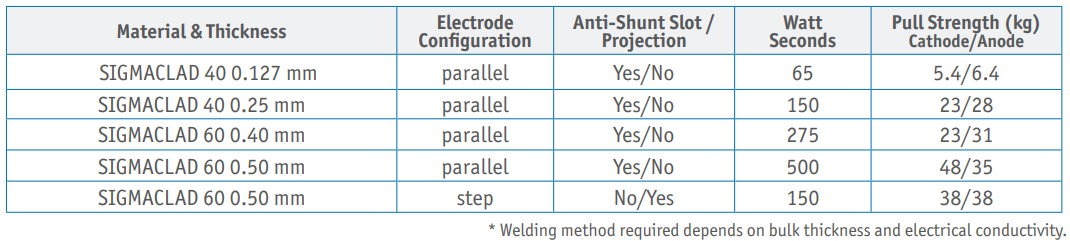

Welding Information

SIGMACLAD as connector material welds readily through the use of anti-shunt slots, weld projections, and/or a step welding process.

Excellent pull strengths are observed for multiple conductivity levels and strip thicknesses.

Good solderability is observed for all SIGMACLAD variants using a Sn/Cu solder with a rosin core.

Power Tools

E-bikes

Small EV's

Drones

Lawn and Yard

E.S.S

Energy Storage Systems

Downloads

"We have chosen SIGMACLAD® for our new generation of battery packs due to the improved conductivity without compromising the resistance weldability. The performance increase leads to a noticeable added value for our customer"

Power Tool Manufacturer