Sense. Control. Protect.

Thermostatic Bimetals are one of the most widely applied families of clad metals. But, what is Thermostatic Bimetal? In its basic form, Thermostatic Bimetal is comprised of two metals with different coefficients of thermal expansion (CTE) that are bonded together. It is this difference in CTE of the component metals that give Thermostatic Bimetals their unique property of bending or curving as a result of an exposure to change in temperature.The amount in curvature the Thermostatic Bimetal experiences is proportional to the temperature change. It is also predictable and it is repeatable. It is these unique properties that make Thermostatic Bimetal useful in any application where it is desirable to sense and react as a function of temperature.

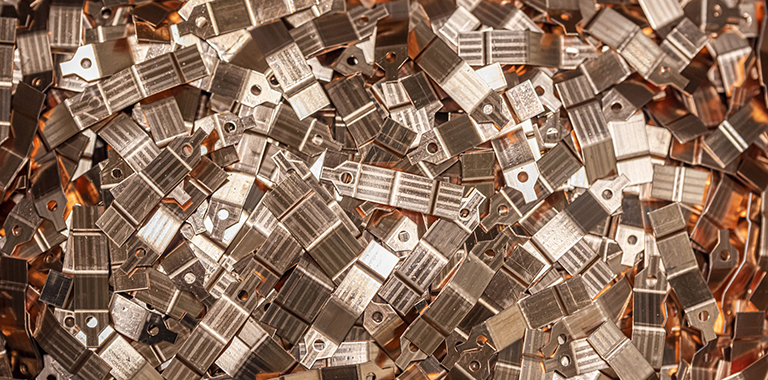

As formed parts, spiral coils, or snap acting discs, this movement can be used to make and break electrical circuits, indicate or compensate for temperature changes, release springs, open or close valves and perform many other repetitive tasks. Because of its reliability, Thermostatic Bimetal is employed as an economical solution for temperature sensing and control applications in a wide range of industries such as; automotive, electrical, HVAC, or home appliance.Whether you are at work, at home, in an airplane, boat or car – virtually anywhere – you are almost always within reach of a Thermostatic Bimetal device.

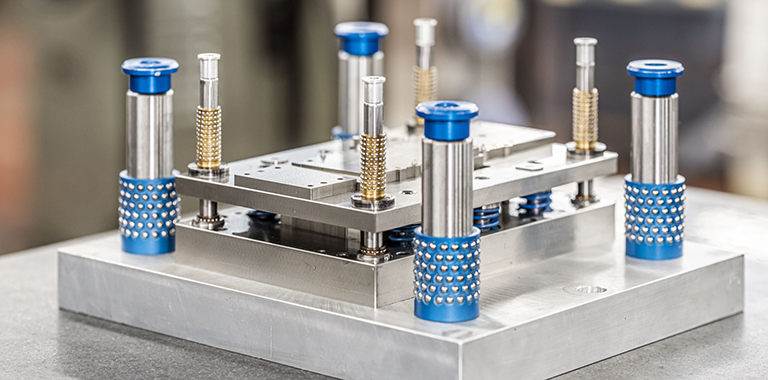

At EMS, we have produced more than one hundred unique Thermostatic Bimetals that can be tailored to meet the specific needs of your application. Production of these high performance metals and parts, and understanding their innumerable applications and the customized processing parameters critical to their performance, has been the heart of our business since its inception.

What can Thermostatic Bimetal devices do?

› Regulate and control temperature on clothes irons, toasters, toaster ovens, coffee makers, ovens, clothes dryers, hair dryers, deep fat fryers, electric blankets, electric frying pans and tea kettles, rice cookers, griddles, grills, and waffle irons, just to name a few

› Protect fluorescent light ballasts from overheating

› Regulate room temperature

› Turn automotive fans on or off

› Record the temperature of sensitive cargo in transport to assure it has not varied from the desired range

› Protect home, office, factory electrical circuits

› Protect aircraft electrical circuits

› Open/close crawl space and attic vents

› Regulate electric range burner temperatures

› Protect electric motors from overloading

› Protect circuitry in computer and peripheral surge protectors

› Provide anti-scald protection in hospital and nursing home showerheads

› Keep self-adjusting drum brakes from over adjusting at elevated temperatures

› Compensate for ambient temperature variations in car and SUV hatch and hood struts

› Compensate for viscosity variations due to temperature changes in automatic transmissions

…And much more