- Home

- About EMS

EMS

Solving thermal, electrical, joining, corrosion, and weight challenges with Engineered Materials Solutions

- Products

Product Catalog

Products that lead with quality!

MenuMenu - Markets

Markets

Your Application – Our Solution

- Technology

Technology

Open the Doors of Design to an Exciting New World of Possibilities

- Resource Center

Resource Center

Keep your-self up to date with our latest information and services!

- Careers

Join us

Engineered Materials Solutions is an Equal Opportunity Employer

Inlay Clad Metal

Advantages of Inlay Clad

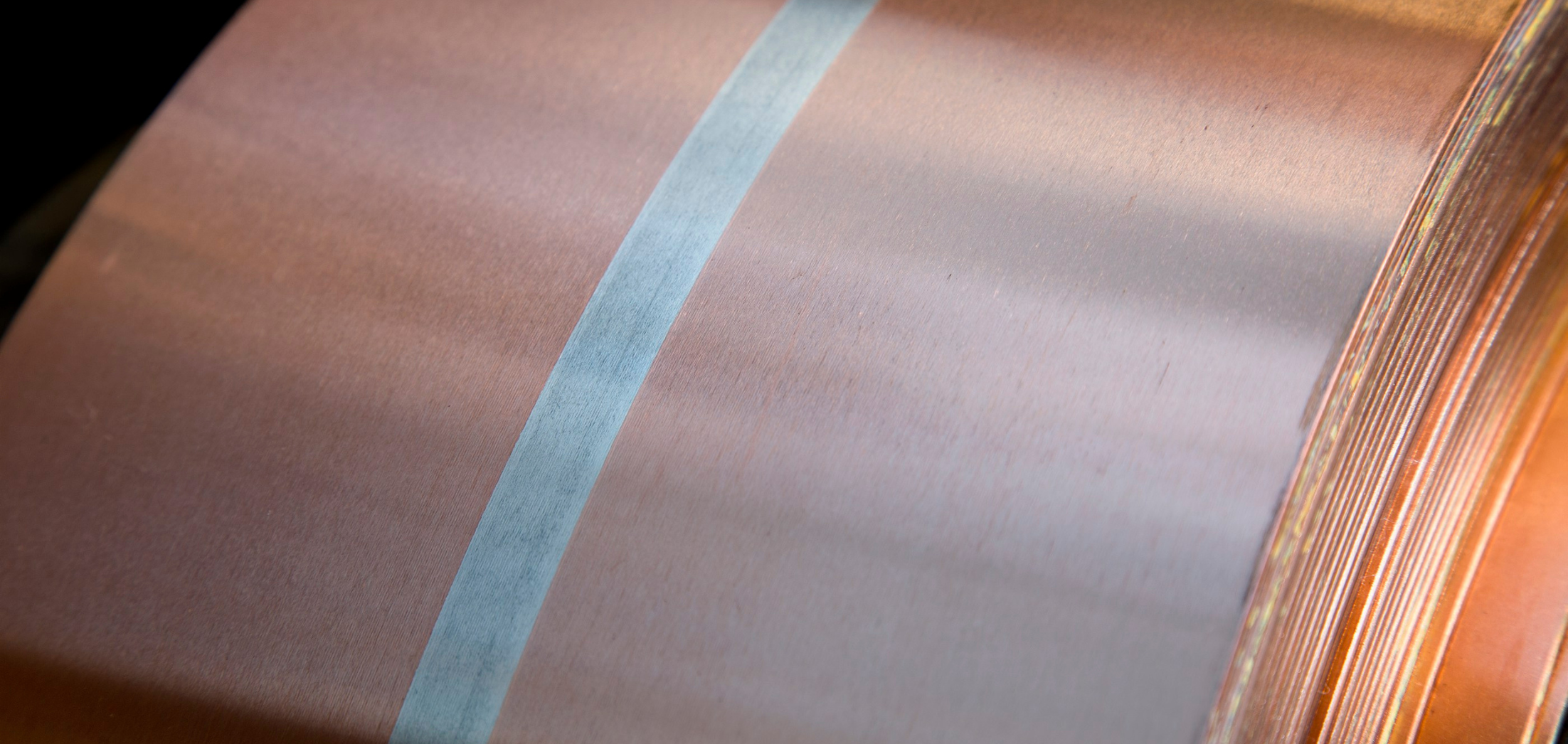

Clad metal inlays feature one or more metal strips bonded (or inlaid) into a base metal strip. This approach provides flexibility allowing the designer to incorporate diverse properties, such as weldability, corrosion resistance, and conductivity, at different locations. It also can reduce cost by positioning more expensive metals only where they are needed.

Our Clad inlays offer advantages over alternate selective coating techniques, such as electroplating, since thicker, porosity-free, more ductile inlays are possible.

Clad metal inlays are available in a wide range of sizes and configurations. The inlay material can be positioned along the edges of the strip, displaced away from the edges, and placed on both the top and bottom sides of the strip. Additionally, inlay and overlay combinations are also available.

The base metal, also known as the “substrate” can be aluminum, copper, bronze, nickel, stainless steel, steel or most any alloy of each. The inlay or “stripe” material can be aluminum, copper, stainless steel, nickel and also their alloys.

Substrate thickness can range from 0.002” – 0.100” and widths up to 7.0”. Stripe depth can be from 2 – 40% of total thickness and widths as narrow as 0.100”. Applications include automotive relays, battery interconnects, consumer electronics, motor protectors and small appliance switches.

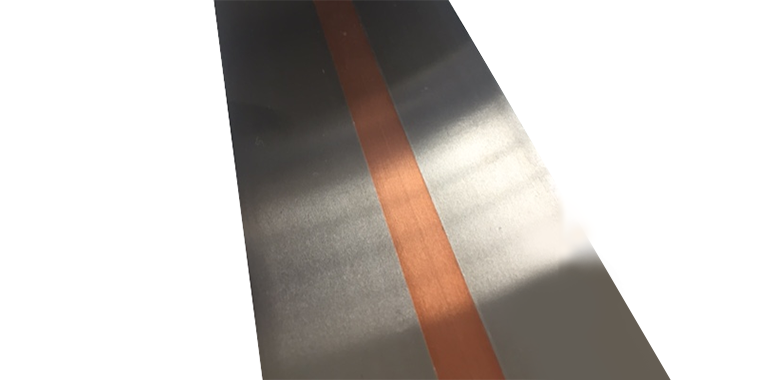

Copper Inlay Stainless Steel

The good electrical and thermal properties of copper can be combined with the mechanical properties of stainless steel using inlay cladding. Using copper only where it is needed provides an economical solution. Stainless steel exhibits good mechanical properties, particularly strength and stiffness which is critical for some applications. Stainless steel is an unusual substrate material that requires special techniques for inlay cladding.