Critical for Safety Applications

Electrical Distribution

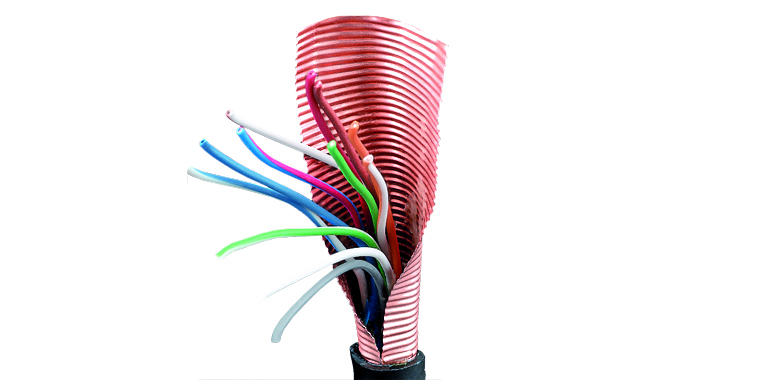

EMS pioneered the development of clad for a wide array of applications in the electrical industry. Copper clad materials combine the high electrical and thermal characteristics of copper, while being safe, reliable and cost effective. It can also protect against mechanical and rodent damage, and errant electrical strikes which can disrupt service and be costly to repair. We can show you how cladding copper can offer excellent electrical conductivity for your product or business.

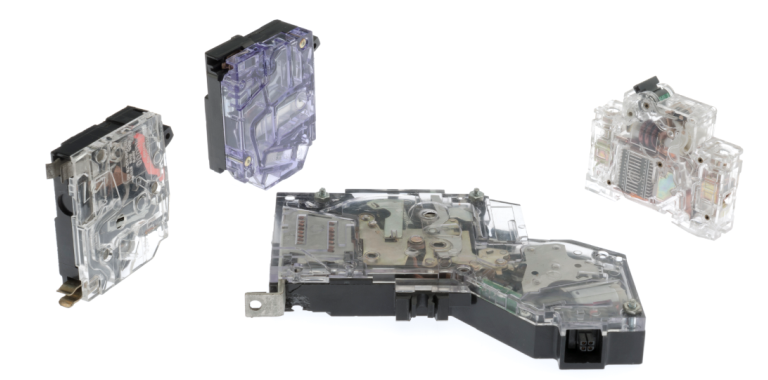

Circuit Breakers

Electrical Grade Thermostatic Bimetal has long been used as the activating element in residential and industrial circuit breakers. When current draw exceeds the circuit’s amperage rating the Thermostatic Bimetal will overheat and trip the breaker which interrupts the current flow through the circuit. The world’s leading producers of circuit breakers rely on the quality and performance of EMS Thermostatic Bimetal Strip and Parts for this critical safety application.

For more information CLICK HERE

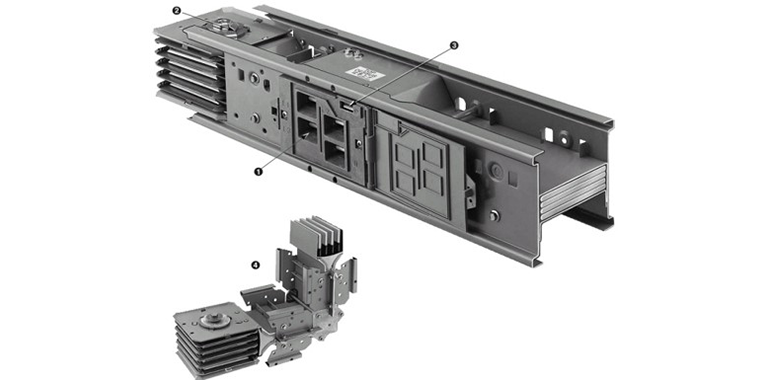

Busbars and Busways

Copper Clad Aluminum combines the light weight benefits of Aluminum with the high electrical and thermal characteristics and excellent heat dissipation of Copper for many applications in the electrical distribution market.

For more information CLICK HERE

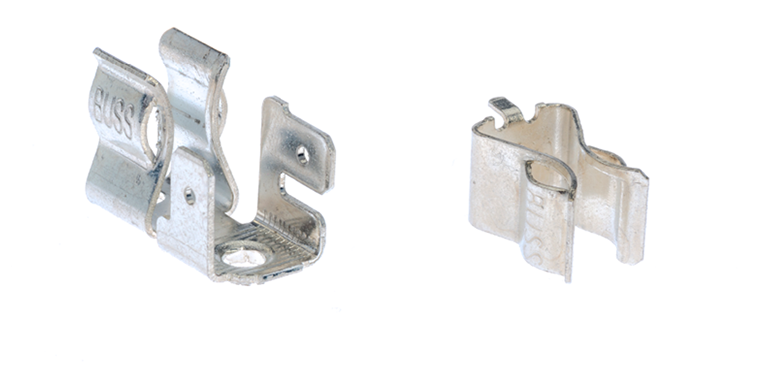

Fuse Clips

Copper Clad Steel combines the physical attributes of steel and high conductivity for applications from flat to canterlever-type springs or parts. Applications such as fuse clips, connectors, terminals, and circuit breaker applications.

For more information CLICK HERE and CLICK HERE