You Can Count On Us

Analysis and Testing Services

We offer you a complete service around Analysis and Testing Service.

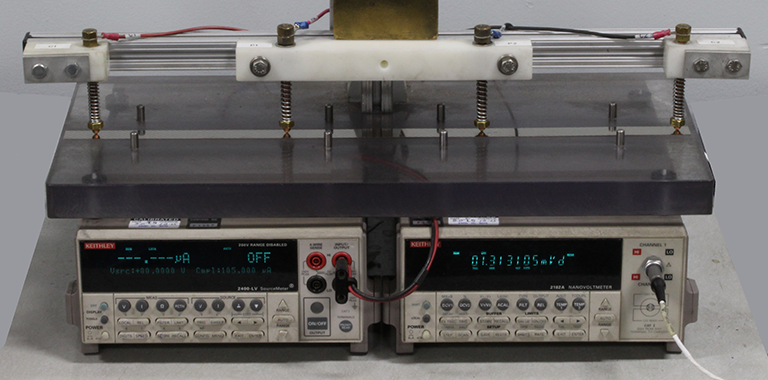

Resistivity

EMS can measure electrical resistivity and electrical conductivity of any type of clad metals strip using a 4 point bridge apparatus

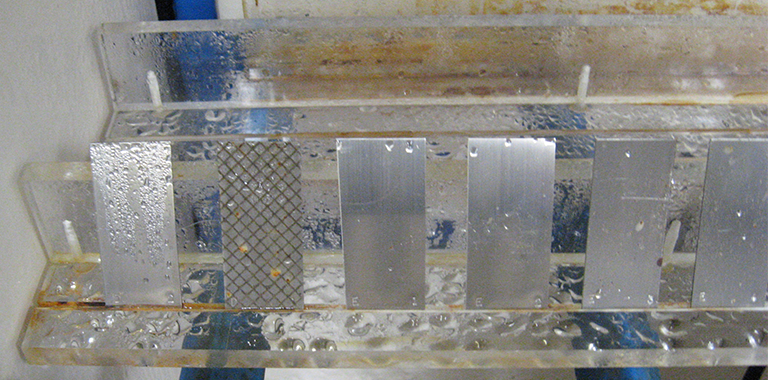

EMS can provide corrosion testing to ASM, ASTM, SAE and other well established standards. Enhanced corrosion performance is primary benefit of clad metals which has led EMS to develop a corrosion lab with following test apparatus: Condensing Humidity, Non-Condensing Humidity, Salt Spray, and Cyclic Immersion.

EMS has been active for over 5 decades testing corrosion behavior and publishing the benefits of clad metals in automotive, telecommunication, architectural and electronic applications.

Cross Section Analysis

EMS has full metallurgical lab capability which allows metal samples to be cross-sectioned, mounted in phenolic molds, polished, and etched for further analysis. After sample preparation, cross-sections area analyzed for grain size, individual clad layer thickness, and clad boundary zone composition.

Layer Thickness Measurement

In addition to optical measurement, EMS uses a Fischerscope measurement device which accurately determines the thickness of the outer clad layers.

Coefficient of Thermal Expansion (CTE)

On site CTE measurement is possible using a theta Dilatronic dilatometer. Both high (+125 C) and low temperature (-55C) ranges can be measured to provide certification of thermostatic bimetals and clads such as Cu/Invar/Cu.

Differential Thermal Analysis:

This thermoanalytic technique provides data on exothermic and endothermic changes that occur in a metal sample compared to a standard. Solidus and liquidus temperatures are important to understand when designing clad metals for applications such as brazing.

Surface Analysis

For applications requiring specific surface roughnesses, EMS uses Mahr surface profilometers both in process and also as part of engineering development. The MarSurf 400 surface texture measuring unit has a range of +/- 250 microns and can report Ra, Rq, Rz and Rmax. The Mahr SD 26 drive unit has a built in datum plane and is suitable for measuring P-profile and for roughness and waviness measurements.

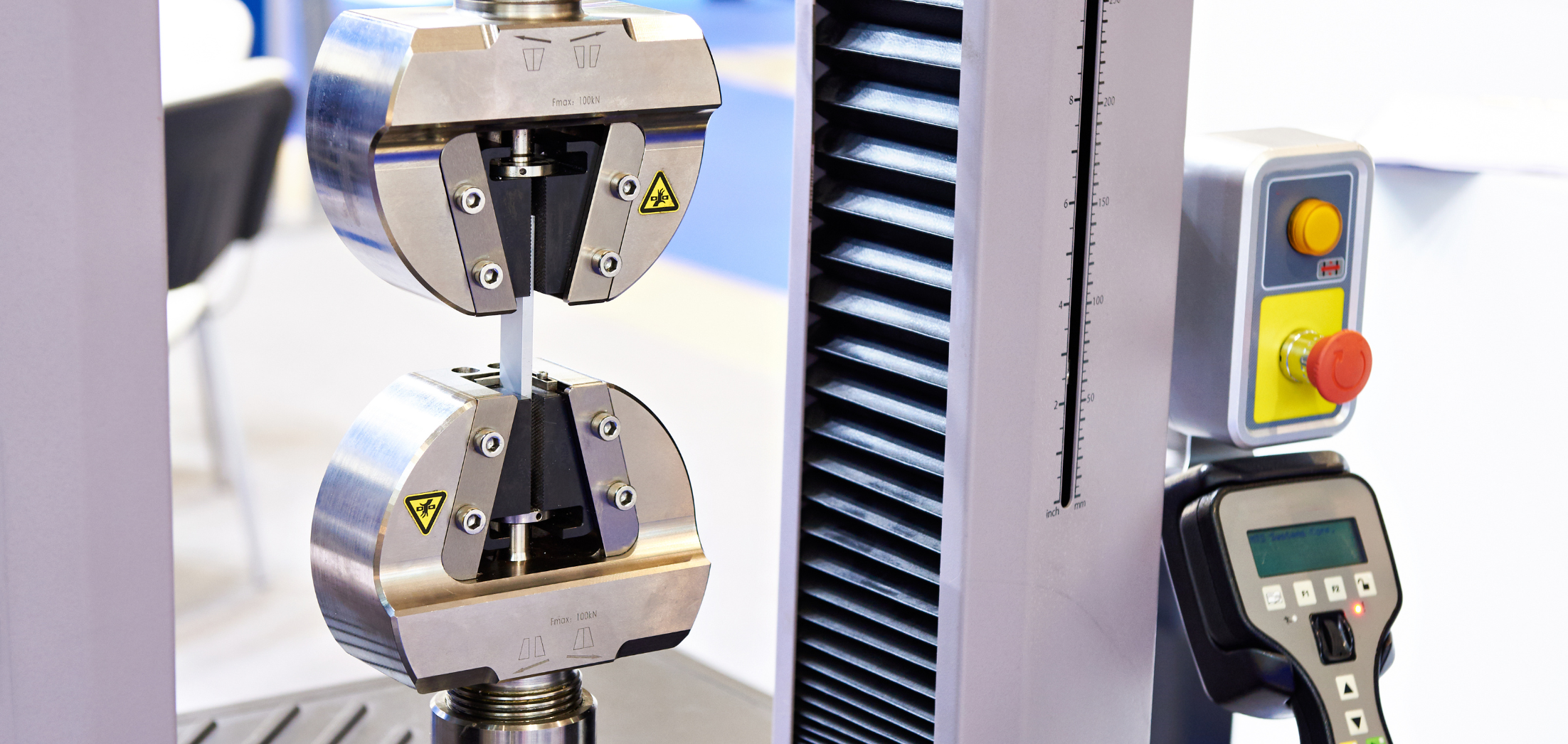

Tensile Testing

EMS tests mechanical properties using an Instron or a Tinius Olson tensile machine depending on the sample thickness. Both can provide yield strength, tensile strength and elongation to break data along with the yield curve. The Instron is also used to test the peel strength between various layers of bonded metals. After making a small separation between the layers, the Instron is used to measure the force necessary to peel the layers in pounds/ inch of width.

Hardness Testing

EMS has both macro-hardness and micro-hardness measuring capabilities. For macro-hardness, EMS can report the using various scales such as Rockwell and Rockwell superficial. Micro-hardness is reported as DPH and Knoop.

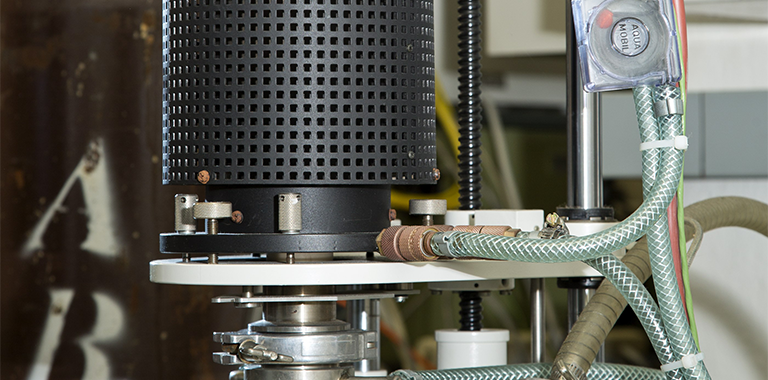

Ductility Testing

Capabilities include Erichsen deep drawing and cup testing which measures ductility and the Swift cup test which measures the limiting drawing ratio on materials.

Gravelometer Testing

Gravelometer testing is designed to evaluate the resistance of material to denting caused by the impacts of gravel and other flying objects in accordance with SAE and ASTM standards. The primary usage of this test is to simulate the effects of the impact of gravel or other debris on automotive parts such as bumpers.