Edge Clad Metal

Advantages of Edge Clad

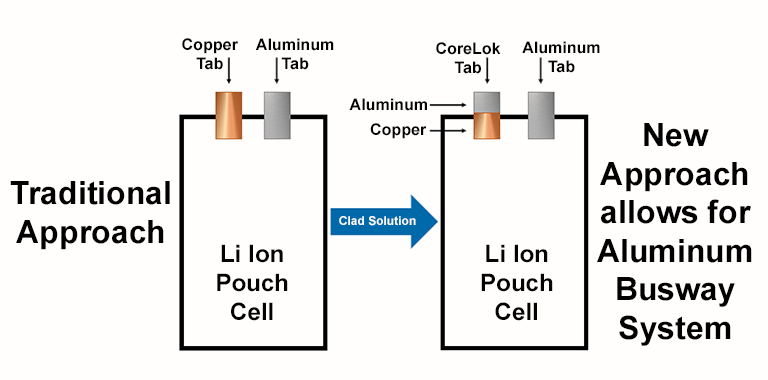

Some metals cannot be joined reliably by traditional welding processes. This includes copper to aluminum which is desired for many Li-Ion battery applications. Edge cladding creates a strong reliable joint that can be used in a variety of applications. The edge clad joint provides not only good mechanical strength, but also good electrical and thermal performance. Unique edge clad solutions can be created for specific customer applications and needs.

Copper Aluminum CoreLok®

CoreLok® edge clad copper to aluminum provides superior electrical conductivity, mechanical strength and thermal performance. The strength of the CoreLok® joint exceeds that of the aluminum alloy. This material can be used to join copper and aluminum battery tabs in a busway system or to replace copper tabs with copper/aluminum tabs allowing for an all aluminum busway design.